Expertise in the field of electrical and mechanical engineering.

63 Years of experience

Abrol Engineering Co. Pvt. Ltd. (AECO) was founded by Mr. M.K. Abrol in 1958 and started with manufacturing

motor starters. Gradually the company diversified into manufacturing of low-tension switch gear, miniature

circuit breakers (MCBs) and distribution equipment in compliance with International standards.

By the year 2000, catering to the Indian Railways became our core strength. Since then, we have added a range of

integral electrical and mechanical rolling stock components to our catalogue and are supplying these to clients like

RDSO, RCF, MCF, ICF, CLW, DLW, BHEL, BEML, RITES and all Zonal Railways.

In the year 2020 AECO has set up a state-of-the-art bunched copper conductor plant with complete Niehoff GmbH machinery.

MISSION

To provide the cable industry with the best quality of products and to ensure the highest level of customer satisfaction.

To deploy state-of-the-art machinery and equipment and to surpass the industry standards and best practices in achieving company’s vision.

VISION

To be the leader in the field of producing copper conductor.

Manufacturing Process

Copper Rod Break Down from 8 mm to 1.6mm

The Niehoff RBD draws 8mm Copper Rod as input material. It has the capability to draw the wire down to diameters between 1.3 to 4.0mm. The copper is sourced from the best raw material suppliers of purest quality. We have state-of-the-art material handling systems in place.

Electro Tin Plating

The Niehoff WPT series is a state-of-the-art Electro-plating machine which is capable of producing tin plated wire from 1mm upto 2.6mm. This technology ensures with best accuracy of n plating thickness from 1μm to 24μm serving a wide range of customer requirements.

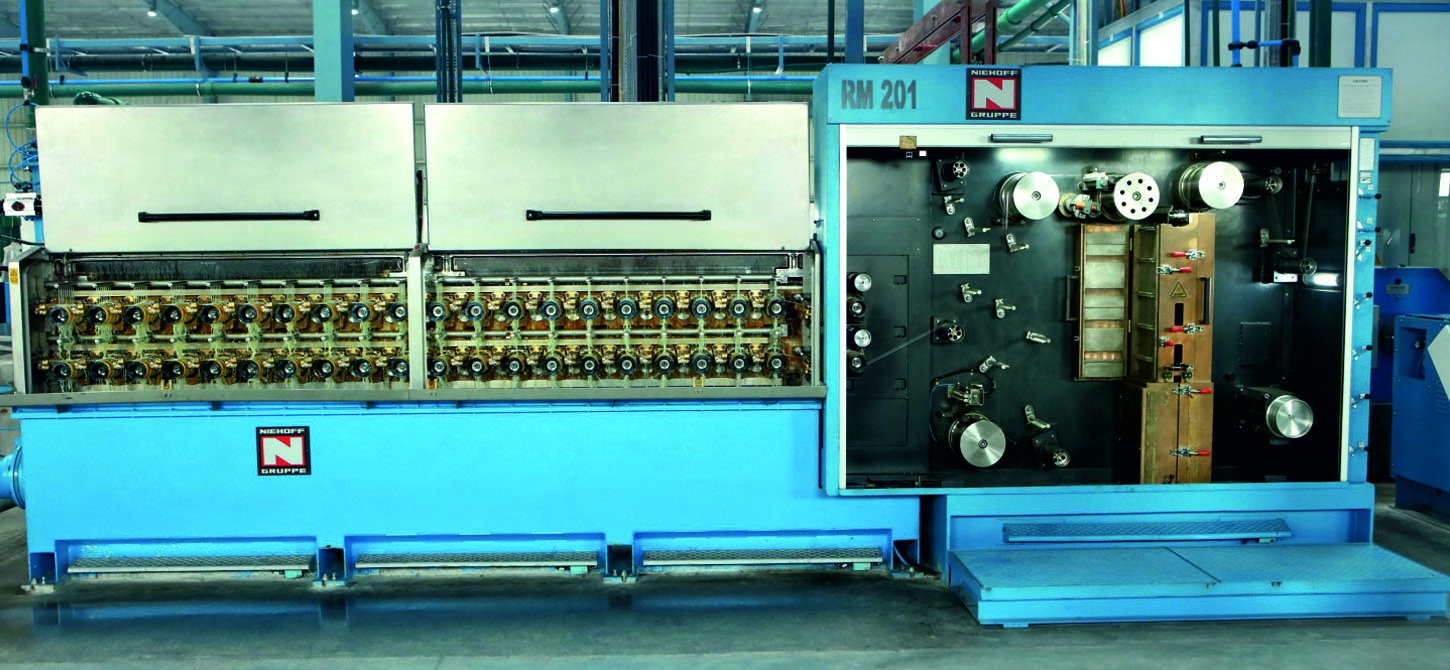

Multi Wire Drawing

The Niehoff Multi Wire Drawing Machine is the latest edition of Niehoff, Germany. This machine is capable to draw 16 wires from 0.50mm to 0.15mm with inline annealing facility.

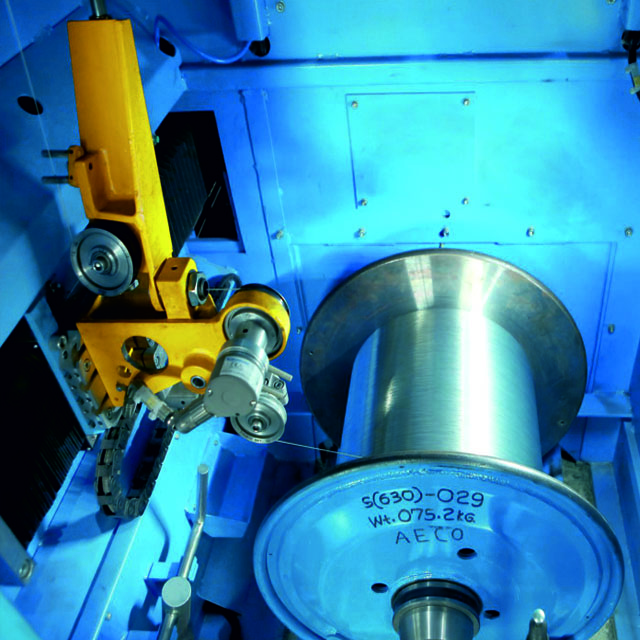

Conductor Stranding

The Niehoff Double Twist Bunchers are capable of bunching bare and tinned copper conductors ranging from 0.5 sqmm to 16 sqmm. These machines are designed to manufacture Unilay & Concentric Conductors.

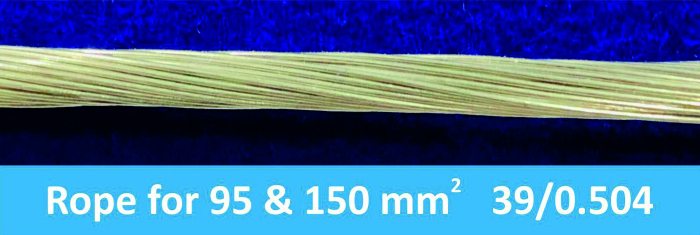

Conductor Rope Stranding

The Niehoff 1250 Buncher is the latest addition with specially designed capability upto 150 sqmm both in bare & tinned conductor manufacturing.

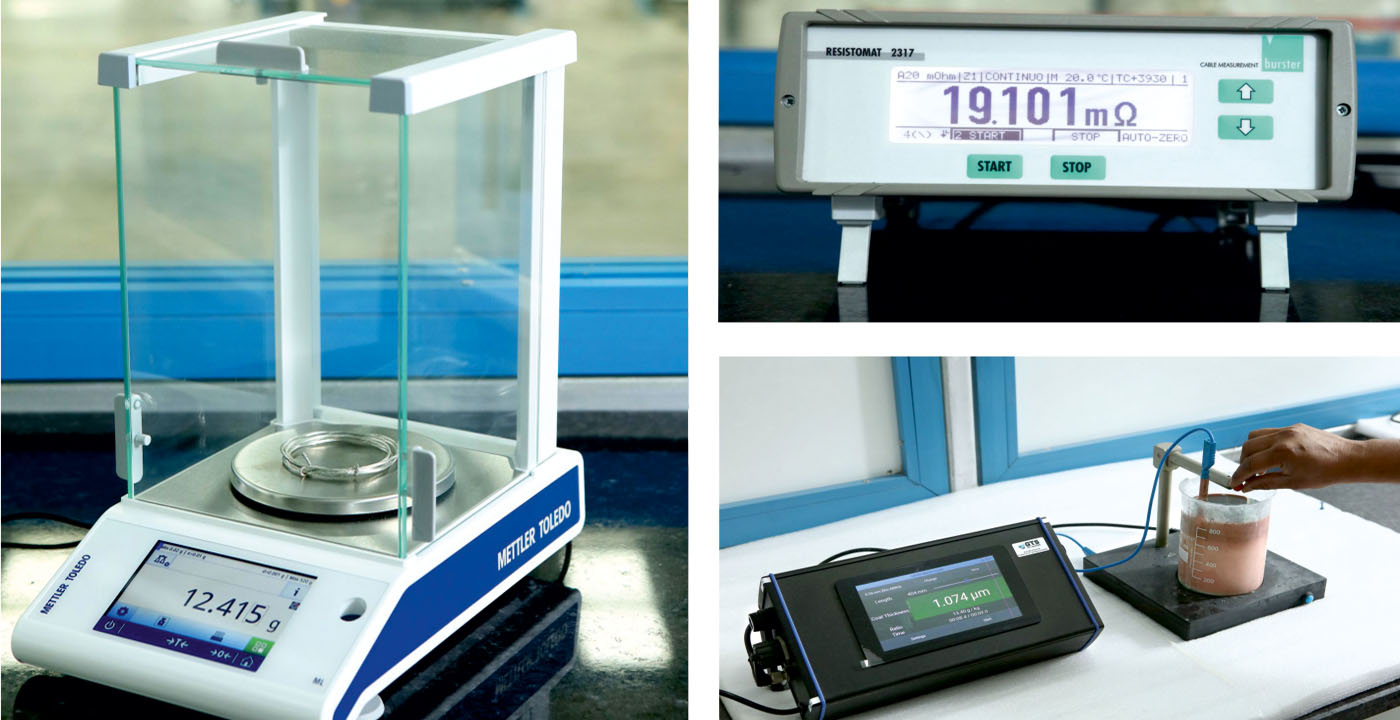

Testing Process

- Computerized Elongation Tester

- Computerized Tensile Tester

- Swiss Tin Thickness Measuring Equipment

- German Conductor Resistance Tester

- Swiss High Accuracy Weighing Equipment

- Digital Diameter Measuring Equipment

- Per Sulphate Test Equipment

Manufacturing Facility

- Niehoff Rod Break Down Machine

- Fully Automatic Tinning line by Niehoff

- Multi Wire Fine Wire Drawing line by Niehoff

- Niehoff Double Twist Bunchers 630mm Spool

- Niehoff Double Twist Bunchers 800mm Spool

- Niehoff Double Twist Bunchers 1250mm Spool

Manufacturing Capacity

VOLUMES (ANNUAL)

Copper Rod Break Down 6000 MT

Electro Tin Plating2500 MT

Fine Wire Drawing2500 MT

Conductor Stranding100,000 km to 200,000 km

Conductor Rope Stranding25,000 km to 75,000 km

Product Specification

- RDSO - Indian Railway standard

- IS8130 - Indian Standard

- EN60228 - International Standard

- BS6360 - British Standard

- JASO D611, JIS3102 - Japanese Standard

- ASTM B173, B172 - American Standard

- VDE 0295 - German Standard

- EN13602 - International Standard

- ISO6722 - International Standard

0.35 sq.mm - 6 sq.mm S/Z Type Bunched/Unilay/Concentric conductors are available in 630 DIN steel spools

6 sq.mm - 16 sq.mm S/Z Type Bunched/Unilay/Concentric conductors are available in 630/800 DIN steel spools

10 sq.mm - 150 sq.mm Unilay/Concentric conductors are available in 630/800/1250 DIN steel spools

Product Range

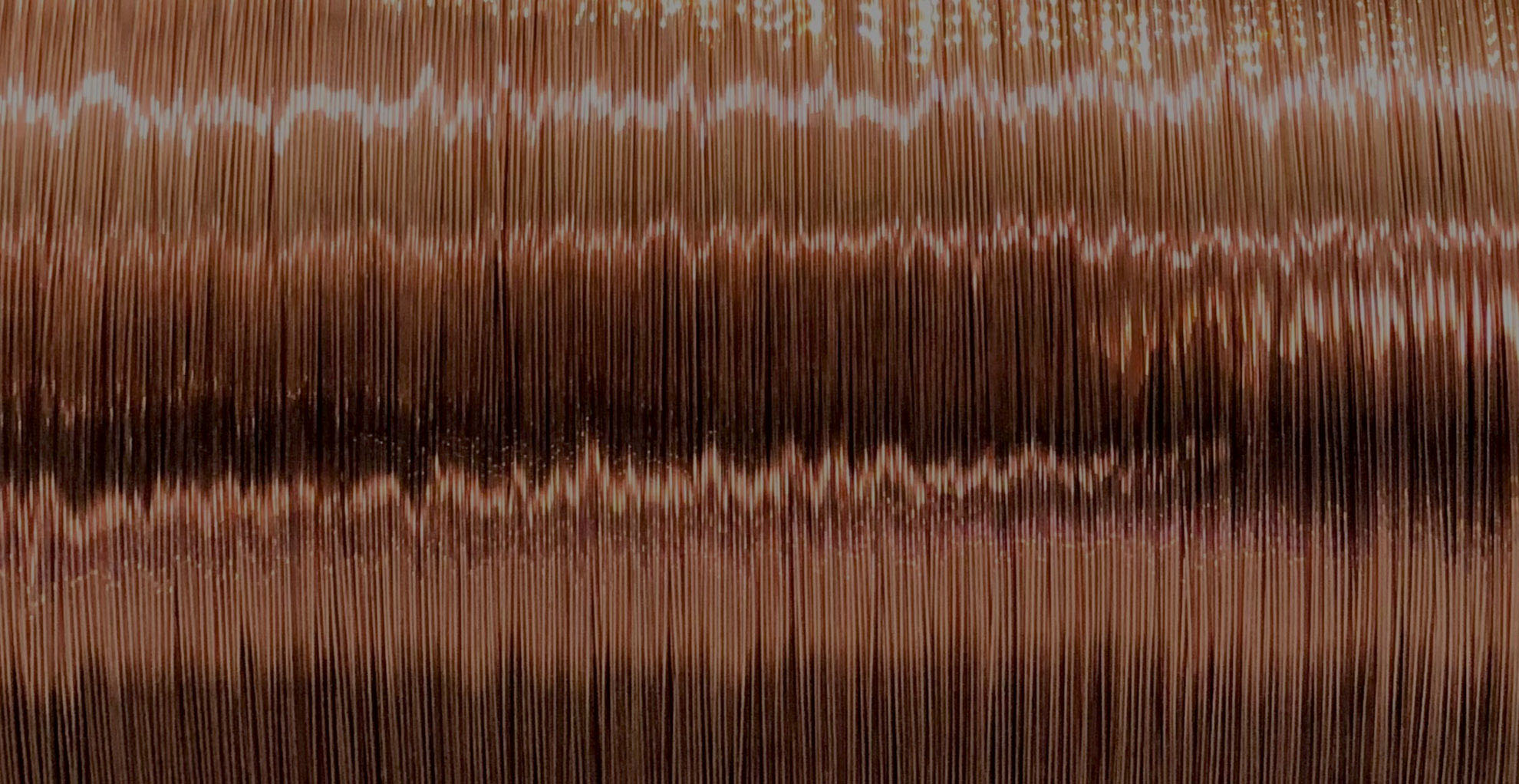

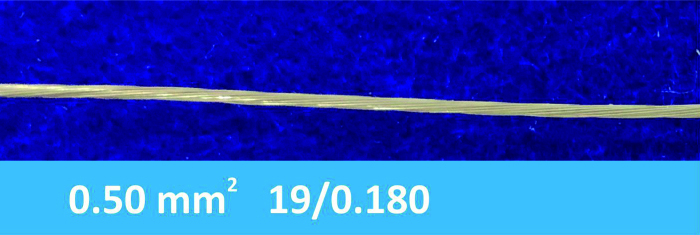

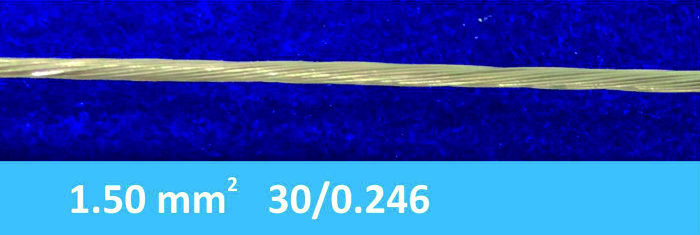

Bunched Conductors

This type of conductor is made up of bunched multi-wires. The wires are twisted together in a random pattern.

Standard bunched conductors are widely used in the cable industry.

Conductor materials:

-- Annealed Bare Copper Conductor

-- Annealed Tin Copper Conductor

Constructions:

-- Bunched/Unilay/Concentric lay constructions are available.

-- These conductors shall be manufactured to meet various specifications and customer requirements.

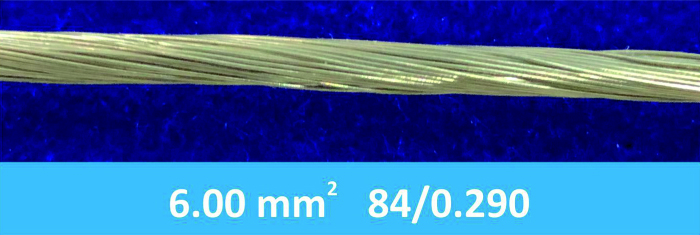

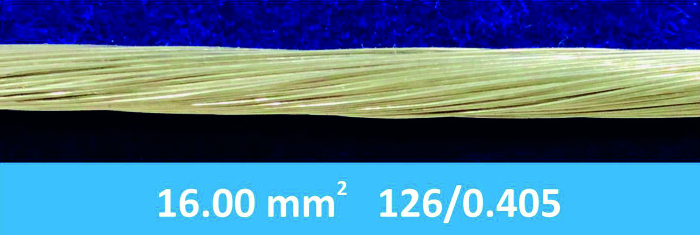

Highly Flexible Tin Plated Ropes and Stranded Conductors

Highly flexible round concentric stranded conductors and ropes

These products have high flexibility and are suitable for cables used in dynamic environments.

Product Range

Available with bare or tin plated copper wires.

Construction

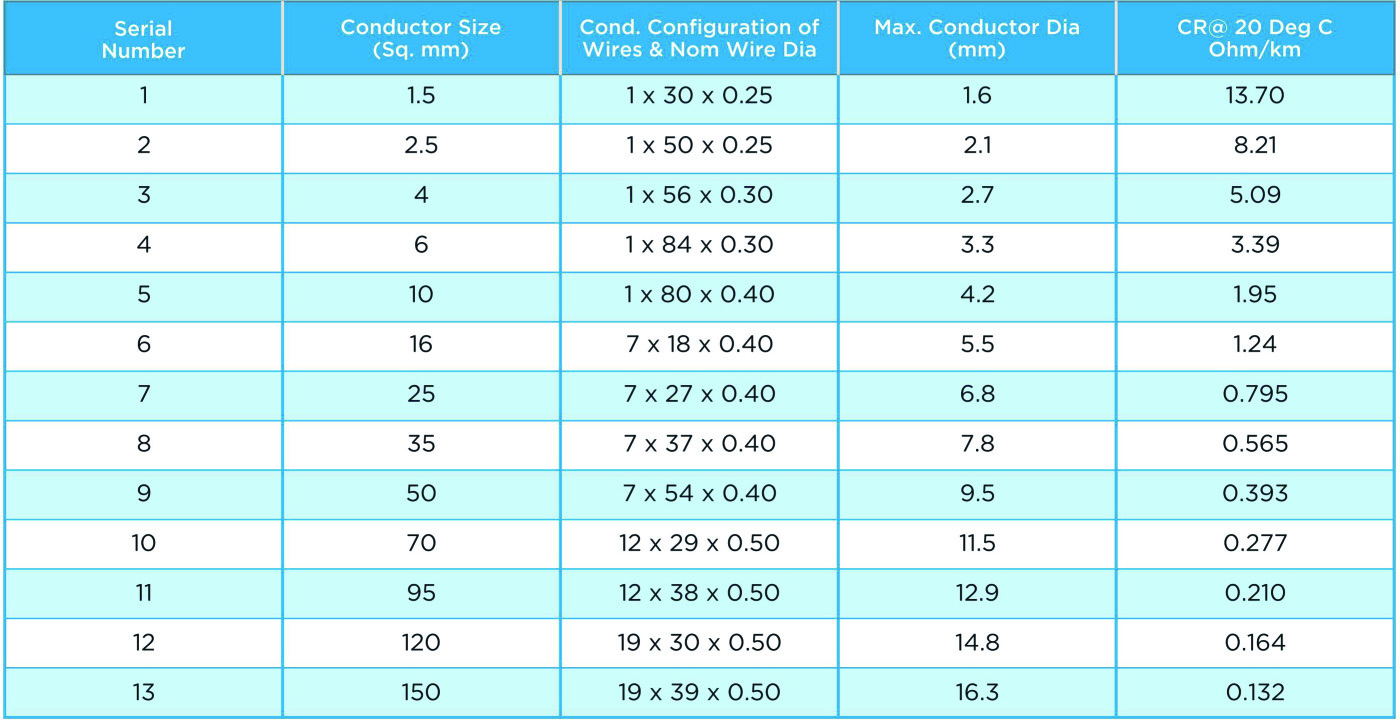

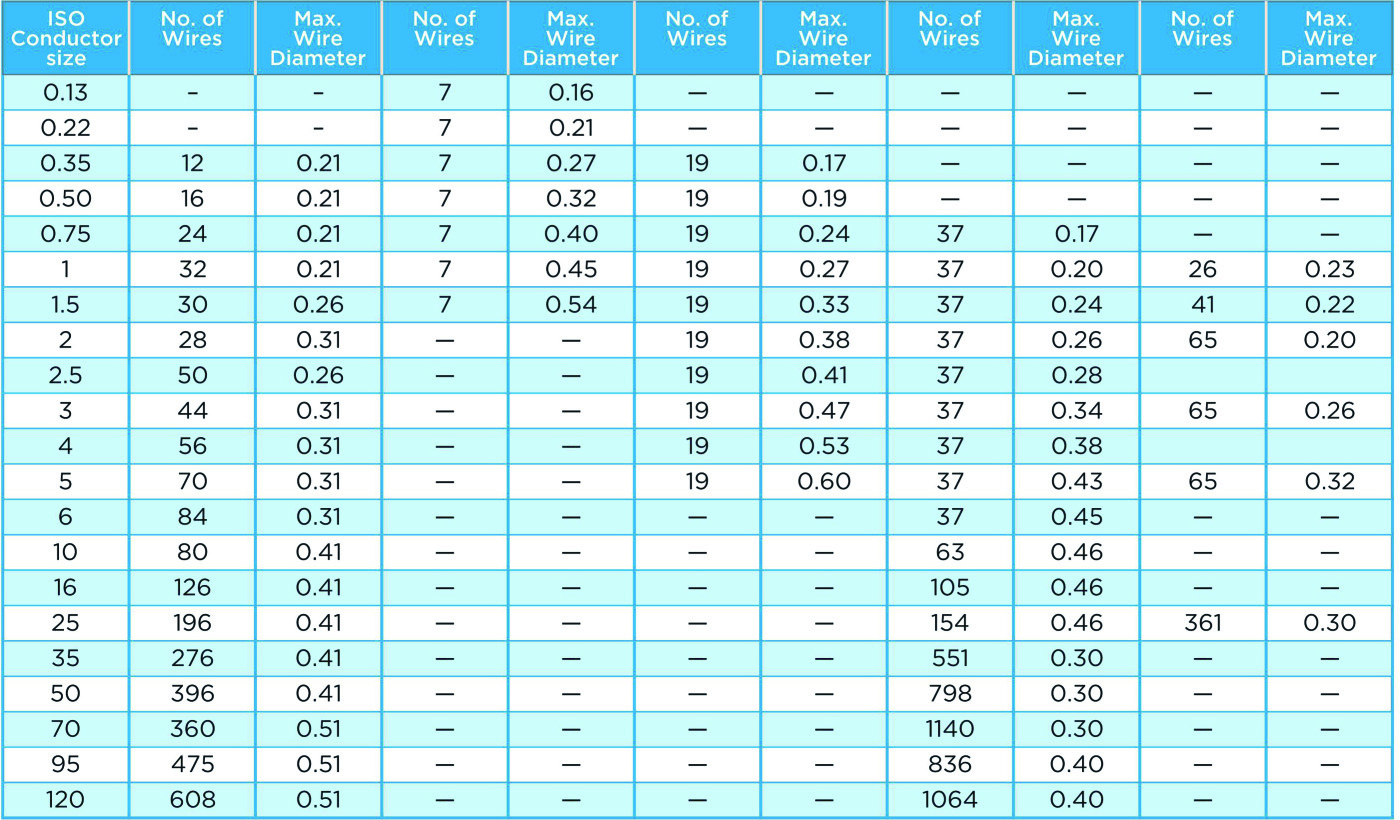

The examples shown in the table below can be manufactured both as bunched conductors and as 7/19 way ropes.

Lay length of bunched conductors: 10-50 mes the overall diameter of the conductor.

Lay length of 7/19 way conductors: 10-50 mes the overall diameter of the conductor.

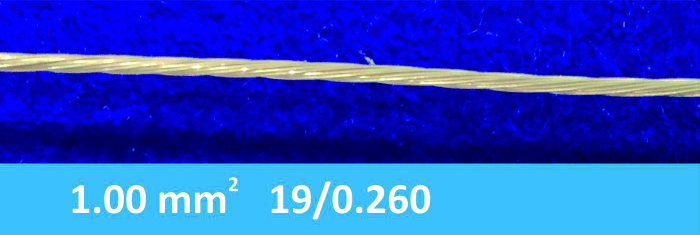

Highly Flexible Copper Conductors for Automotive Industry

Highly flexible round concentric stranded conductors and ropes

These products have high flexibility and are suitable for cables used in dynamic environments.

Product Range

Available with bare or tin plated copper wires.

Construction

The examples shown in the table below ISO 6722 manufactured both as bunched conductors and as 7/19 way ropes.

Lay length of bunched conductors: 10-50 mes the overall diameter of the conductor.

Lay length of 7/19 way conductors: 10-50 mes the overall diameter of the conductor.

Packaging

- Up to 4 Sq. mm 630MM DIN Steel Spools

- 4 to 16 Sq.mm 630MM & 800MM DIN Steel Spools

- 10 to 150 Sq. mm DIN 800 and 1250 Steel Spools on Steel Pallets

- All Spools and Pallets on returnable basis